by Karl McLetchie, Global Foundation for Ocean Exploration

J Dunn, NOAA Office of Ocean Exploration and Research

June 24, 2019

A squat lobster was sampled around 722 meters (2,369 feet) using the suction sampler during the first dive of the Windows to the Deep 2019 expedition. Image courtesy of the NOAA Office of Ocean Exploration and Research, Windows to the Deep 2019. Download larger version (jpg, 2.3 MB).

Windows to the Deep 2019 is the first live-streamed expedition during which the remotely operated vehicle (ROV) Deep Discoverer (D2) will use its new suction sampler. A suction sampler is an underwater vacuum for collecting biological samples that are too small, too delicate, or too quick to pick up using the jaws of D2’s hydraulic manipulator. Some of these deep-sea animals could include pelagic animals, fish, and other mobile fauna, like squat lobsters.

Once the samples are suctioned into the holding jars, they will remain within D2 until the ROV is brought back on board NOAA Ship Okeanos Explorer. At this point, the samples are transferred to the ship’s wet lab. Each of the sample jars is intended for a single suction event, but often multiple biological or geological samples could be suctioned into one jar. In the wet lab, all samples, both suction samples and traditional samples, are separated and investigated. For the current expedition, the lead scientists handling the samples are geologist Amy Wagner (California State University Sacramento) and biologist Alexis Weinnig (Temple University). The samples are imaged in the lab and paired with ROV images. All of the associated information for each sample is entered into a database and shared with the public. The samples themselves are preserved for transportation to data centers such as the Smithsonian National Museum of Natural History and are then made available to the public.

This squat lobster was collected during the first dive of the Windows to the Deep 2019 expedition. It was collected using the suction sampler and placed in a tank on NOAA Ship Okeanos Explorer, allowing scientists the opportunity to take detailed imagery for identification. Image courtesy of the NOAA Office of Ocean Exploration and Research, Windows to the Deep 2019. Download larger version (jpg, 4.7 MB).

The new suction sampler was designed and built over the winter by the Global Foundation for Ocean Exploration’s (GFOE) engineering team. It was successfully tested during an engineering dive as part of the Shakedown and Seatrials 2019 expedition in the spring.

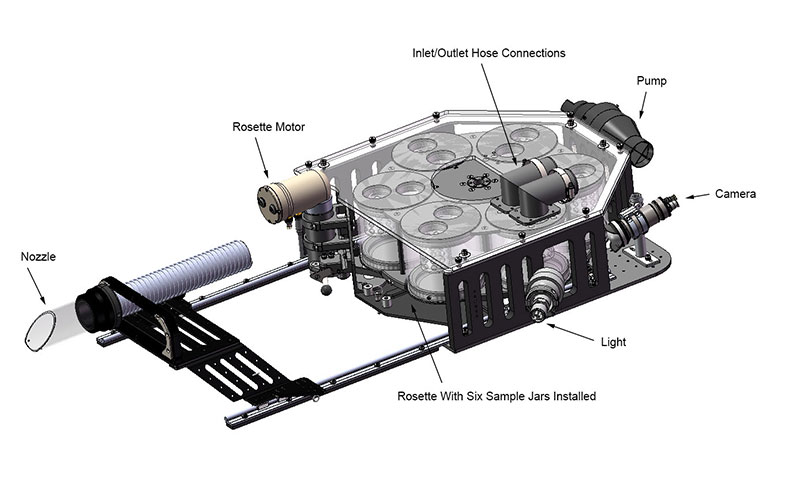

The image below is an overview of the sampler’s components and highlights the complexity of the system. Mechanical, electrical, software, and video engineers all collaborated to design and build the system – from the two six-kilometer-rated electric motors that drive the rosette and pump to the graphical user interface (GUI) that allows the pilots to select the active sample jar and adjust pump speed and direction.

Drawing of the suction sampler and the rosette of six sample jars. Image courtesy of the Global Foundation for Ocean Exploration. Download larger version (jpg, 344 KB).

When a benthic sample is requested by the science community, the pilot first grabs the nozzle with the hydraulic manipulator. The nozzle is attached to 12 feet of flexible hose so that the pilot can reach a sample anywhere in the field of view of D2’s camera. Once the nozzle is in place for a sample, the pilot rotates the rosette to select one of the 2.7-liter jars to suck the sample into. There are five sample jars outfitted with filters to prevent the sample from being sucked into the pump. The sixth jar is a “bypass” jar. It has no filter and is used to flush contaminants after each sample. Finally, the pilot turns up the flow on the suction pump until the sample moves through the nozzle and appears in the active jar in view of the dedicated jar camera.

Additional options and features include a variety of filter mesh sizes from five microns up to the standard half inch holes; a variety of nozzles including clear polycarbonate for standard samples, titanium for hydrothermal samples, and clear cone for midwater samples; and a variable speed pump with forward and reverse.

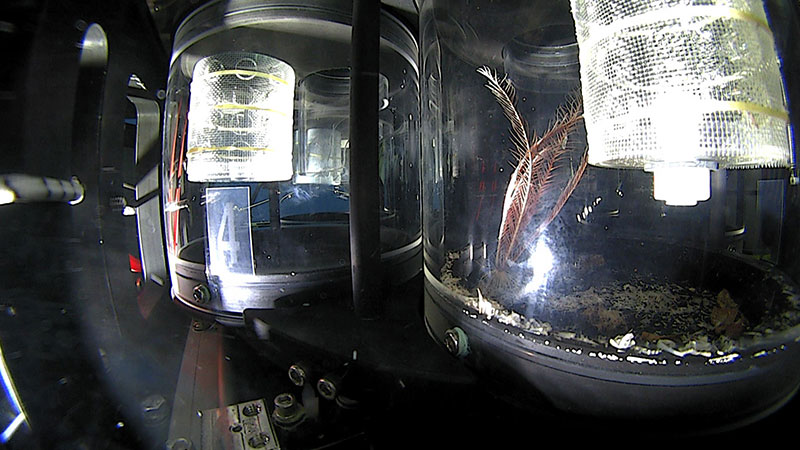

Close up of the new suction sampler and the rosette of sample jars on the remotely operated vehicle Deep Discoverer. Image courtesy of NOAA Office of Ocean Exploration and Research, Windows to the Deep 2019. Download larger version (jpg, 4.4 MB).

Close-up image of the suction sampler sample jars with one of them containing a crinoid sample from Dive 2 of the Window to the Deep 2019 expedition. Image courtesy of NOAA Office of Ocean Exploration and Research, Windows to the Deep 2019. Download larger version (jpg, 1.2 MB).