by Grady Bolan, University of Rhode Island

November 29, 2018

Sunrise from the stern of NOAA Ship Okeanos Explorer. Image courtesy of the NOAA Office of Ocean Exploration and Research, Mapping Deepwater Areas in the Caribbean and South Atlantic Bight. Download larger version (jpg, 395 KB).

Hi! My name is Grady Bolan and I am part of the University of Rhode Island senior design team researching 3D printing in a dynamic environment. In today’s log, I wanted to discuss our schedule and some of the things we have seen so far. I will also give an update on how our printing is going.

In order to maintain a constant watch on the printer, we have had to come up with a watch schedule for the team members. Our schedule is based on four hours on, eight hours off, eight hours on, and then four hours off. This is staggered for everyone, allowing for some overlap so no one is alone while on watch. We need someone watching the printer around the clock because we cannot afford to waste any time. We want to make sure the printer is constantly running a print. This means being up at weird hours. Yesterday, I had a four-hour shift from 2 am to 6 am and was able to see the sunrise over Puerto Rico.

During those odd hours, there isn’t much to do and just watching the printer will knock you right out. Fortunately, there is so much to do to stay awake! You can go outside get some fresh air, take a stroll around the ship, grab a coffee from the galley, watch downloaded movies, work out, eat ice cream, or procrastinate with your homework. And everyone on board is so friendly! Last night, LT Nick Pawlenko and ENS Brian Caldwell gave our team a tour of the bridge. This will be one of the highlights for me, and I plan on going back up there to harass the bridge officers during our trip.

Castillo del Morro (known as El Morro). Image courtesy of the NOAA Office of Ocean Exploration and Research, Mapping Deepwater Areas in the Caribbean and South Atlantic Bight. Download larger version (jpg, 482 KB).

On our way out of Puerto Rico, we got a good view of Castillo del Morro in San Juan. It was a beautiful sight, and I was told that it is one of the oldest forts in Northern America that is still standing today. But now that we are underway, the pressure is on us. We need to try and effectively get all the prints we want done on the short voyage to the Bahamas. This means NO more watching the beautiful sunsets!

Sunset off the port side of the Okeanos Explorer. Image courtesy of the NOAA Office of Ocean Exploration and Research, Mapping Deepwater Areas in the Caribbean and South Atlantic Bight. Download larger version (jpg, 480 KB).

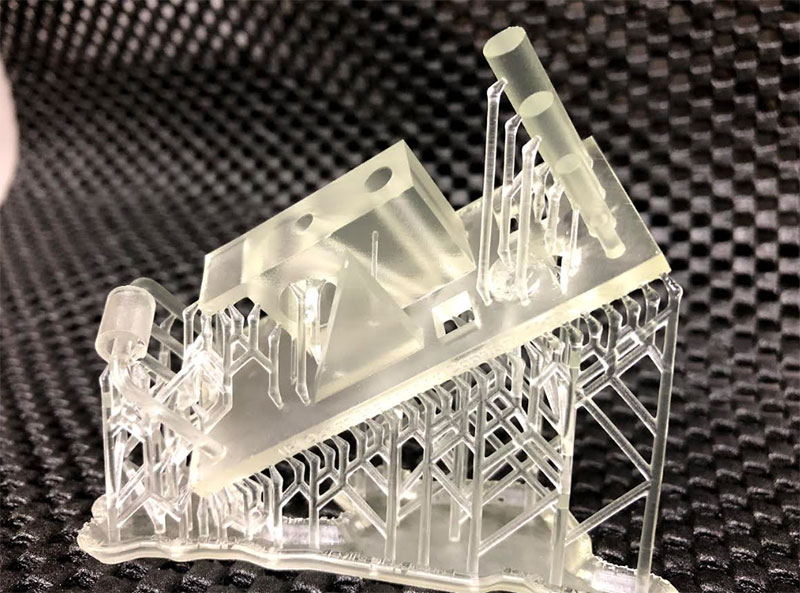

We also want to make sure we are able to get our batch print with the active stabilization system (GyroPro), the passive system (Gymbal, GyroPro turned off), and then with no platform. We predict that the bench test will not work or will take too long as the printer will need to stop in between curing each layer. We also suspect that there will be a difference in the qualitative and quantitative data we collect from the active and passive prints because of the vibrations created by the Gyros. Yesterday after we left the dock, we started our active system print, which took nine hours to complete. Below is the ‘devil’s playground’ mentioned in Josh’s log.

Completed ‘devil’s playground’. Image courtesy of the NOAA Office of Ocean Exploration and Research, Mapping Deepwater Areas in the Caribbean and South Atlantic Bight. Download larger version (jpg, 486 KB).

So far, the prints look great and we are looking forward to doing an analysis onshore. Looking ahead, we have started printing on a passive stabilization printer and then will try to test the batch on the bench.

Just to close out, here is a picture of Josh and I looking the part.

Josh and Grady being professionals. Image courtesy of the NOAA Office of Ocean Exploration and Research, Mapping Deepwater Areas in the Caribbean and South Atlantic Bight. Download larger version (jpg, 537 KB).