by Kelley Elliott, Expedition Coordinator, NOAA Office of Ocean Exploration and Research

Mashkoor Malik, Mapping Lead, NOAA Office of Ocean Exploration and Research

Dan Rogers, ROV Dive Supervisor, Global Foundation for Ocean Exploration

July 9, 2017

Ship systems and equipment were off for several weeks during the dry dock period. Part of the shakedown period includes literally turning on the power and rebooting all of the onboard computer systems to ensure the software is working and up-to-date. One computer in particular took a long time to bring online as the system had to install a lot of updates–120,641 to be exact. Image courtesy of the NOAA Office of Ocean Exploration and Research, 2017 Laulima O Ka Moana. Download larger version (jpg, 3.9 MB).

NOAA Ship Okeanos Explorer recently completed a dry dock period where she received routine maintenance, underwent repairs, and received upgrades to various systems. After this period, the next step in vessel operations is to “shake down” the system by operating and running the ship to test and ensure that the completed maintenance, repairs and upgrades are working properly.

The first four days of operations for this expedition are dedicated to shakedown operations. This includes literally turning on the power and rebooting all of the onboard computer systems and testing to ensure they work and are functioning and communicating properly. While every department will be testing and working on a variety of software and systems, there are a few key activities we spend the majority of this time addressing with ship operations.

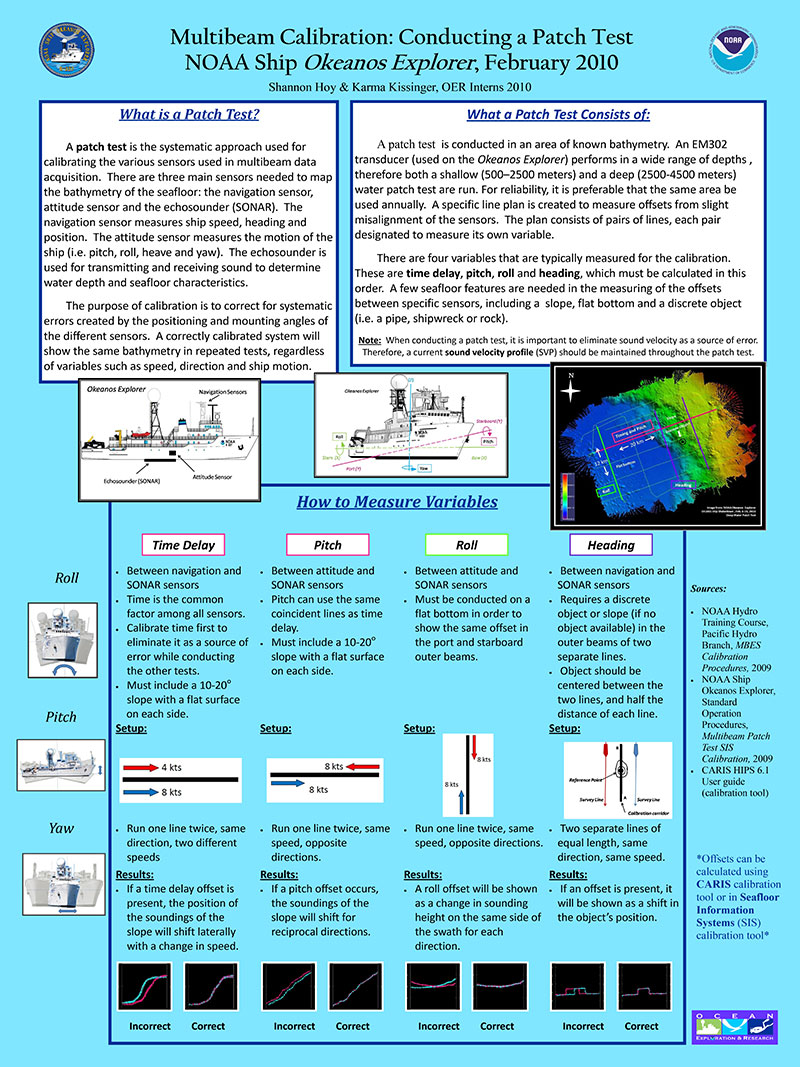

The shake down of the ship’s sonar systems ensures that sonars are operable and are receiving all the necessary input from several of the ancillary sensors. The ship’s multibeam system (EM 302, 30 kHz) requires a very accurate estimate of 3D geometry in which the sonar is installed to be able to form acoustic beams accurately. This geometry of installation, i.e. angular offsets in 3D, is measured through a “patch test.” The ancillary instruments that provide information to the EM 302, including the sound speed sensor at sonar head, heading, vessel motion (heave, roll, pitch, yaw), will also be tested during the shakedown.

Learn more about what a multibeam patch test is and what it consists of by reviewing this poster developed by Okeanos Explorer mapping interns in 2010. Image courtesy of the NOAA Office of Ocean Exploration and Research. Download larger version (jpg, 10.7 MB).

Telepresence Engineer, Roland Brian, and Senior Electrical Engineer, Dave Wright, verifying configuration of the telepresence network switch in the ship’s rack room. During shakedown operations, the ship-to-shore video streams need to be re-established. Image courtesy of the NOAA Office of Ocean Exploration and Research, 2017 Laulima O Ka Moana. Download larger version (jpg, 4.4 MB).

Some of these tests are simply to ensure that data are flowing out of ancillary sensors, and other tests include maneuvering the ship over specific survey lines or making the ship turn sharply to confirm that heading accuracy can be maintained (calibration of GNSS Azimuth Measurement—or “GAMS”—system).

To run these tests, the foremost requirement was to turn all the systems on and ensure that all appropriate software is running and up to date. As the ship’s equipment was off for several weeks during the dry dock period, the updates alone can be a significant portion of the shake down.

Besides the EM 302, other sonar systems to be tested during this shakedown include the single beam fisheries echo sounder (EK 60), sub-bottom profiler (Knudsen 3.5 kHz), and Acoustic Doppler Current Profiler (ADCP, 38, 300 kHz). A few small test surveys are also being planned to ensure that sonars are able to perform together with no interference among them.

Dynamic Positioning (DP) is a computer-based control system that automatically maintains a ship’s position and heading in deep water. DP uses a mathematical model of the ship that receives data from various reference systems and sensors, including GPS, acoustic transponders, wind sensors, motion sensors, and gyrocompasses. Using these tools, the DP system can calculate the needed thruster force and steering angle so the ship can maintain its position in a variety of environmental conditions without anchoring to the seafloor. This capability is key to allowing precise positioning of the ship and therefore also the remotely operated vehicle (ROV) on the seafloor during dives.

Upgrades were made to the DP system during dry dock and we will spend several days testing the system. A Kongsberg engineer will be onboard to provide training on the use of the system to the ship’s bridge officers.

Kongsberg DP Technician, Michael Neal, provides training on use of the ship’s Dynamic Positioning system to NOAA Corps Officers ENS Anna Hallingstad and LT Aaron Colohon. Image courtesy of the NOAA Office of Ocean Exploration and Research, 2017 Laulima O Ka Moana. Download larger version (jpg, 13.5 MB).

Ultra-Short Baseline (USBL) is an acoustic positioning system that is used on the ROVs. It allows the engineers to see where the vehicles are relative to the ship during a dive. This is important in navigating the vehicles through potentially hazardous terrain on the bottom of the ocean, as well as keeping track of them in the water column.

Performing a proper calibration is key to making sure that we receive accurate information about the location of the ROVs while at depth.

Global Foundation for Ocean Exploration Engineers Chris Ritter and Don Liberatore carry the USBL transponder after successful calibration and recovery of the unit. Image courtesy of the NOAA Office of Ocean Exploration and Research, 2017 Laulima O Ka Moana. Download larger version (jpg, 7.5 MB).

ROV “shakedown” dives provide opportunities for our engineers to test the functionality of onboard sensors, cameras, and other important components. They also provide pilots with a chance to practice new techniques for driving the ROV and using the sample collection manipulator arm, without the normal operational pressures of a science-focused dive. This particular shakedown dive is focused on the continued training of our younger and newer engineers.