by David Casagrande, Global Foundation for Ocean Exploration

July 28, 2017

On Tuesday, July 18, 2017, at 1:13 PM, while diving on an unnamed seamount near Johnston Atoll approximately 800 miles west of Hawaii, remotely operated vehicle (ROV) Deep Discoverer encountered a problem. The type of problem which causes the ROV Navigator to report to the Bridge that, “The vehicle has lost power and communications—bail out, bearing 225, speed 0.5 knots.” The type of problem which forces a “dead vehicle recovery,” ends a dive early, and cancels dives for the next two days. The following is an account of what happened, and how the problem was fixed.

ROV Deep Discoverer (D2) and Camera Platform Seirios make up a two-body ROV system for exploring ocean depths. Connected to D2 by a short neutrally buoyant tether, Seirios hangs below the ship, providing lighting and an overhead view, while decoupling the ship’s (sometimes significant) motion from D2 to allow smooth camera views and precise sampling on the bottom.

There is, of course, a third body in the system: Our ship and home at sea, NOAA Ship Okeanos Explorer. Between the Okeanos Explorer and Seirios is an eight kilometer long steel cable, 0.68 inches in diameter (the “six-eight wire”), bringing electrical power from the ship down to the vehicles and carrying signals and video feeds back and forth through optical fibers. It’s kept on a massive storage drum deep in the belly of the ship, neatly layered by a level wind, and paid out and hauled in every day by the traction winch.

The .68 traction winch and storage drum which pay out and haul in Seirios every dive. Image courtesy of Annie White, GFOE. Download larger version (jpg, 13.5 MB).

After making five laps around the traction winch, the wire heads straight up through the ship’s deck, around a flag block, across the deck to the overboarding sheave on the A-frame, and finally down into the water and to Seirios. Despite being mostly invisible to those not on board, the .68 wire and winch make up a vital component of the Okeanos Explorer exploration mission. And this wire is where the problem occurred.

Dive 06 of the expedition began like most others. An easy launch at 8:15 AM was followed by a quick 40-minute descent down to 1,240 meters (~4,070 feet). D2 landed on the first waypoint, and proceeded up the ridge. At 1:13 PM, D2 and Seirios were drawing 9 amps from the ship’s 450 volt three-phase supply, typical for a dive at this depth. The next second, 483 amps. And two seconds later, zero. The ship-board ROV power system simultaneously detected the over-current event and the electrical short in the .68 wire which had caused it, shutting off power. We now had a “dead vehicle” on the bottom of the ocean.

Step one: Get Deep Discoverer back on board. The Navigator called up the Bridge and asked to execute the bail-out, a pre-planned route bringing the ROV away from the terrain and into deeper, safer water. At the same time, the emergency acoustic tracking beacons on both vehicles were activated, and the Co-pilot started hauling in on the winch, bringing Seirios up to match D2’s buoyancy and keep the vehicles in a safe configuration. Meanwhile, the electrical team worked on the ROV power supply, seeing if anything could be done from the surface to restore power. In a word: No.

A dead vehicle recovery is one of many potential emergencies at sea we plan for and rehearse regularly. By the time the ROV reached the surface, streaming behind the ship right down the center line, thanks to careful ship driving, the ship’s crew and ROV team were ready to bring Seirios and D2 back on board without incident. Not even the delicate lighting swing arms, left extended by the loss of power, were damaged.

Step two: Remove the damaged section of wire. The termination, the end of the wire which attaches to Seirios, was the most likely culprit, as it experiences the most wear and tear during launch, recovery, and while in the water. We disconnected the .68 from Seirios, pulled out a few meters of wire to get beyond the damaged section, and made our cut. Easy enough.

Step three: Re-terminate the .68 mechanically to hold the weight of Seirios, and electrically and optically to carry power and data. While the mechanical team worked in the hanger, the electrical team began peeling back layers of steel armor to access the wire’s core, containing the electrical conductors and optical fibers.

Assembly of mechanical termination on .68 wire (right) and peeling back armor over electrical and fiber core (left). Image courtesy of Annie White, GFOE. Download larger version (jpg, 7.7 MB).

The core was led into the workshop for the delicate task ahead. But first, a quick test to confirm that the damaged section had in fact been removed.

It had not. The short wasn’t in the termination. It was time for some detective work. The 483 amps the system briefly drew was enough power to melt metal, fusing together the copper conductors and optical fibers at the site of the “short.” This may not sound like a good thing, but it is what allowed us to locate the fault somewhere in the 8-kilometer wire to better than 0.1 percent accuracy, and ultimately fix the problem.

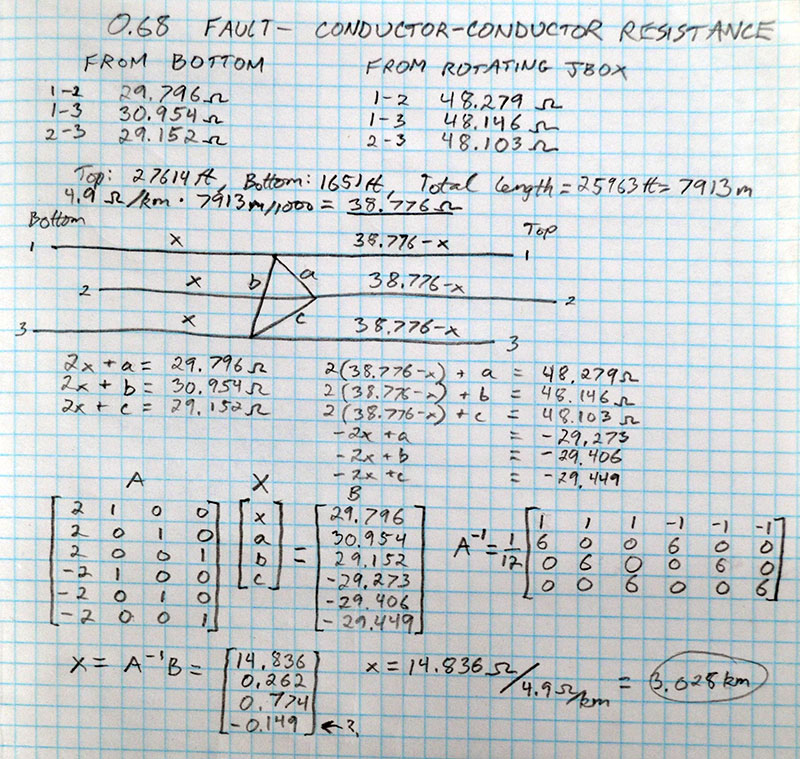

“Short” Locating Method 1: Electrical resistance. Normally isolated, the electrical conductors were connected together at the site of the fault. From the Seirios end of the wire, measure the resistance between two conductors. Make the same measurement from the ship side. With a bit of algebra, you can work out approximately how far up the wire to look. Result: About three kilometers. Not what we were hoping for.

Solving for the location of the short from measurements of electrical resistance. Image courtesy of David Casagrande, GFOE. Download larger version (jpg, 5.4 MB).

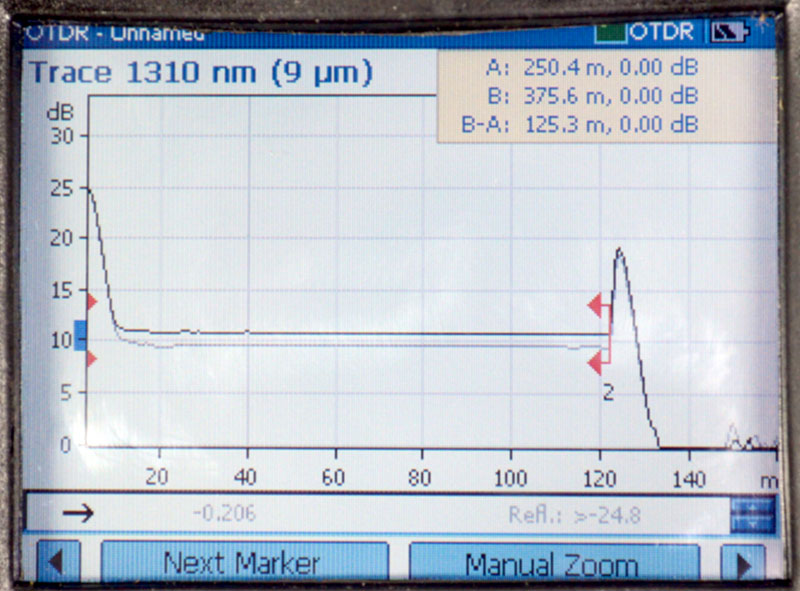

“Short” Locating Method 2: An Optical Time-Domain Reflectometer (OTDR). It may sound like something out of Star Trek, but the principle behind this instrument is very simple: Shine a light down one of the optical fibers, time how long it takes for the reflection off the broken part to return, and multiply by the speed of light to get distance.

OTDR trace showing a fault in the optical fiber 122 meters from the end. Image courtesy of David Casagrande, GFOE. Download larger version (jpg, 2.8 MB).

Just make sure to use an accurate stopwatch: the full round trip took just under three microseconds, and if you want to find the fault with a precision of one meter, you need to resolve time to the nanosecond. Not a problem for the OTDR, it lives for this. Hook it up to the fiber, press Auto Test, and wait 30 seconds. Result: 2,851 meters (9,353.675 feet), exactly.

Now we knew where the fault was, but we had a new problem: how to remove almost three kilometers of wire from the drum, and what to do with it. A dozen ideas were discussed, some more creative than others. Only one was possible at sea, three days from the nearest port. We would pull the wire off the drum, route it up two levels to a clear part of the deck, and form it into a massive coil: 2,900 meters of it, all by hand.

Work began immediately, laying down plywood and plastic to protect the deck and wire from each other and building a wooden corral to keep the wire coil contained. The first loop was laid down just after lunch. Forty minutes later, we took our first break, exhausted. Three-hundred meters (985 feet) down, 10 percent. All we needed to do was repeat that nine more times. This was possible.

The first few loops of wire are laid out. Image courtesy of Annie White, GFOE. Download larger version (jpg, 9.1 MB).

We kicked up the winch speed and made it to one kilometer (3,280 feet) after another hour. We now had 80 coils of wire laid out neatly on the deck. The next push was to 1,500 meters (4,921 feet), with a spontaneous group rendition of Bon Jovi’s “Livin’ on a Prayer” (“Wooah, we’re halfway there / Livin’ on a prayer / Take my hand and we’ll make it, I swear…”).

Home stretch, we were getting good at this. The winch was running at 20 meters (65 feet) per minute, nearly the speed at which the ROV descends during dives. In a highly choreographed process, we laid down almost two new coils per minute. Two-thousand meters (6562 feet). Over, under, over, under, over, under. Finally, just before dinner, we reached 2,700 meters (8,858 feet).

We made the first cut, and peeled back three layers of armor. Electrical resistance indicated that the short was just ahead. The Fiber Response Team, battling wind and sea spray, performed a quick fiber termination.

The team anxiously awaits the results of a fiber test, which will give the final distance to the fault. Image courtesy of Roland Brian, GFOE. Download larger version (jpg, 1.9 MB).

We hooked up the OTR and shot it. Almost perfect agreement with our earlier measurements, just 122 meters (400 feet) to go.

Another 180 meters (591 feet) removed, enough to get well past the failed section. Cut. Peel back armor. Expose core. Electrical test: nearly infinite insulation resistance. Optical: No loss, a clear path all the way through. We got it.

The next morning, the mechanical team started on the new termination, creating the attachment point for Seirios and pull testing it well beyond the force ever experienced during a dive. Meanwhile, the electrical team worked with the ship’s engineers to confirm that the brief but extreme current draw had not caused damage to any ship systems or the ROV power supply. After the pull test, the electrical and optical terminations were performed and tested. Finally, we reattached the wire to Seirios, went through our standard pre-dive checks, and powered on. Everything worked perfectly.

By Friday, everything was back to normal. Early morning pre-dives were followed by a quick breakfast and an on-time launch. It was a great dive, through a stunning landscape of canyons and ridges, scattered with corals, sponges, and other deep-sea fauna.

We were back to normal, with just a few sore muscles and sunburns to remind us of what had happened. And a giant, 7,000-pound coil of wire.

The ROV team stands proudly in the center of their coil of wire. Image courtesy of Annie White, GFOE. Download larger version (jpg, 8.2 MB).