By Bradley W. Barr, Ph.D., NOAA Office of National Marine Sanctuaries Maritime Heritage Program, Co-Principal Investigator and Chief Scientist

October 5, 2015

Final, assembled drop camera design. Image courtesy of NOAA/ONMS. Download larger version (jpg, 1.4 MB).

The University of New Hampshire’s School of Marine Science and Ocean Engineering offers a two-semester design project course, funded in part by New Hampshire Sea Grant, required of all fourth-year undergraduate students majoring in Mechanical Engineering. Having heard about this from colleagues at the university, I thought this might offer some opportunities to assist in the design of the drop camera system we needed to develop for the “Lost Whaling Fleets” mission.

Grace welding a side of the frame. Image courtesy of NOAA/ONMS. Download larger version (jpg, 1 MB).

While drop camera systems are reasonably common as a research tool, they have been mostly designed using the “trial and error” method—building something based on an existing system familiar to the researcher and modifying it based on the experience of using it in the field. There is little published research available on developing drop camera frames, the underwater cameras used to collect video, or how those cameras are controlled and operated to insure the video and images collected are of high quality.

Perhaps some talented and motivated undergraduate mechanical engineering students could apply what they have learned to address this lack of systematic and robust knowledge about how these systems should be designed and operated. Grace, Myles, and Devon expressed enthusiasm for taking on this challenge and approached me after I presented the proposal for the project to the class in the Fall of 2014.

Starting with little more than the design requirements I had provided them, over the remainder of the fall and throughout the Spring Semester of 2015, they diligently pursued the answers we were seeking.

Devon bending the hook for the tether. Image courtesy of NOAA/ONMS. Download larger version (jpg, 1.3 MB).

While the final design for the drop camera system we used for the mission was somewhat different than the fully functioning prototype they designed and built, the results of their research and “hands-on” development efforts were instrumental in refining and optimizing the ultimate design of the mission system. Their findings guided and informed the fabrication of our drop camera frame and selection of cameras and underwater lighting and led to the identification of the cutting-edge underwater wireless control system that supported the collection of high-definition video of potential whaling shipwreck sites identified in the mapping of the survey area in this historically significant place along the coast of the Chukchi Sea.

We are grateful to Grace, Myles, and Devon for their excellent work and to the University of New Hampshire School of Marine Science and Ocean Engineering for the opportunity to collaborate with these talented young mechanical engineers.

By Grace Cardarelli, Myles Riddell, and Devon Snell, University of New Hampshire’s School of Marine Science and Ocean Engineering

As a University of New Hampshire senior project team, we were tasked to develop a cost-efficient and mission-specific drop camera system to explore shipwrecks off the coast of Wainwright, Alaska. Some of the important design requirements included the size of the system, the shipping capability, and once again, the cost.

Our first concern was the physical frame. We wanted to make sure the frame was heavy enough to drop straight down underwater, yet small enough to be shipped and to not snag on underwater debris. For the frame, we chose 3/8-inch stainless steel round bar. This material is corrosion resistant in a marine salt environment. Round bar, as opposed to flat bar, prevents any unintentional movement of the drop camera system due to drag or turbulence.

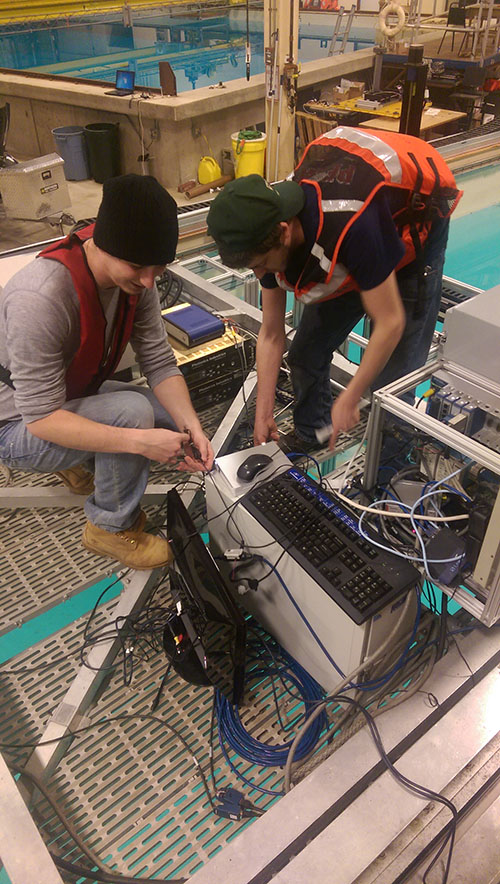

Myles and Devon on the tow carriage setting up the experiment. Image courtesy of NOAA/ONMS. Download larger version (jpg, 1.7 MB).

The first testing we performed was a depth analysis to calculate how the depth and orientation of the drop camera changed with the speed of the vessel. We modeled the drop camera as a mass-damper system and experimentally found the damping constant based on the speed of the vessel. We were also able to experimentally find the tow angle of the drop camera, which influenced the design of the section of the frame that holds the cameras.

To record video, we chose to include three GoPro cameras in our design: two facing down and to the sides for data collection and one facing down and forward to assist in safely navigating the system while it was deployed above the seabed.

The navigational camera uses a hard-wired underwater housing, custom-made by Eye of Mine, to waterproof the cameras and with cables to send live video from, and power to, the camera. The navigational camera was attached to a laptop to show real-time images of what the drop camera was encountering on the seabed.

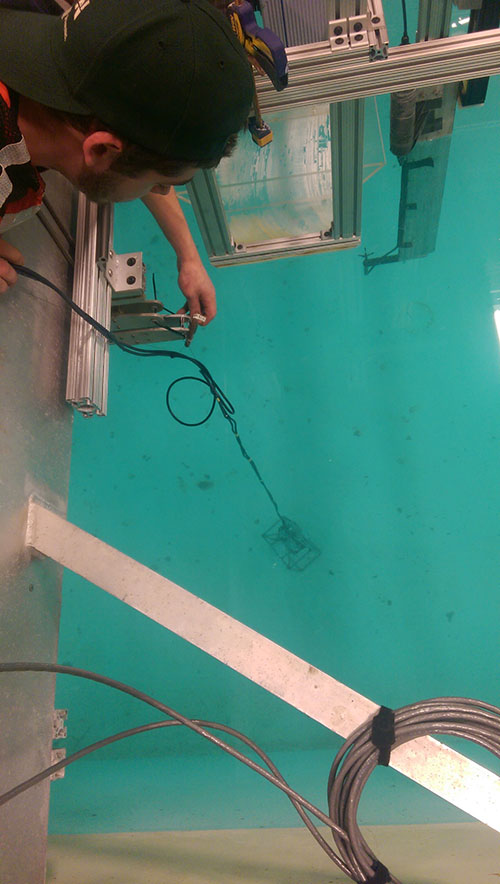

Devon lowering the drop camera system into the tow tank to begin the experiments. Image courtesy of NOAA/ONMS. Download larger version (jpg, 1.3 MB).

A waterproof pressure sensor was made using PVC pipe, an analog pressure sensor, and controlled by an ardiuno microprocessor to record the depth of the drop camera. A Globalsat GPS was connected to the laptop in order to record the specific latitude and longitude of the drop camera. Big Blue dive lights were chosen because of their reliability and their power. Red filters were installed on the cameras to reduce the effects of light attenuation underwater. LabView software was used to consolidate the live feed video, GPS data, and pressure data from the drop camera system into one simple user interface displayed on the laptop.

The second round of testing we performed, in the large test tanks at the University of New Hampshire Ocean Engineering Laboratory, was to test alternative fin designs. During the original testing, the direction of the forward-facing navigational camera was inconsistent at times. Testing both one and two airfoil-type fin designs, fabricated using a 3-D printer, we towed the drop camera system in one direction and immediately changed direction to test the response time. We found that the drop camera straightened out faster with two fins and while towing, was steadier than with one fin.